By Travis Goldman

Irrigation distribution uniformity plays a key role in the success of crop stand, yield, and quality. Optimized pressures within a well-designed irrigation system can provide the best results but even the best design isn’t safe with compromised pressure. Through real-time, in-field irrigation data we can evaluate irrigations in our crops from drip to full-coverage sprinklers.

Along California’s Central Coast wine region, for example, we hardly see a flat piece of ground to farm. Each ranch is unique with positive and negative head pressures that drive changes throughout the irrigation system.

Rolling hills can provide a challenge with varying irrigation pressure and can lead to poor uniformity if minimum pressure is not met. Pressure compensated emitters work great in these conditions, but they too have to meet the minimum designed pressures.

In the example of Netafim’s pressure compensated emitters, these emitters are rated between 7 and 45 psi. Systems that don’t meet the required 7 psi can lose roughly 50% of their output based off projected output flow. A common size that we run into in the region is the 0.5 GPH emitter. Through the use of Hourtau in-line pressure transducers, we can better monitor when an irrigation set drops below the required PSI and log this information.

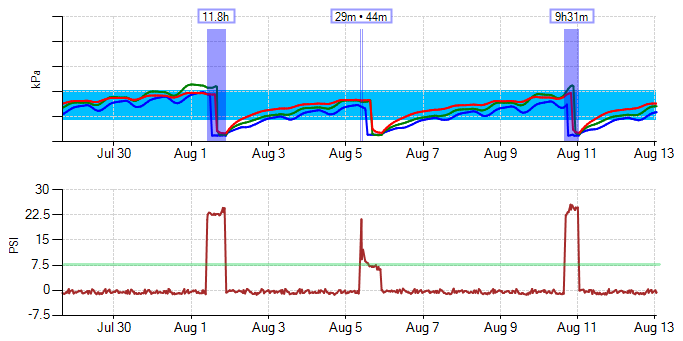

In the example below, we can identify that an irrigation on Aug. 5 ran for 13 hours but only 1.25 of those hours ran under the designed pressure. The issue was easily corrected for the next irrigation after confirming that another block was opened shortly after and ran at the same time. The following irrigation on Aug. 10 ran without the other block and pressure was restored back to the irrigation design specifications.

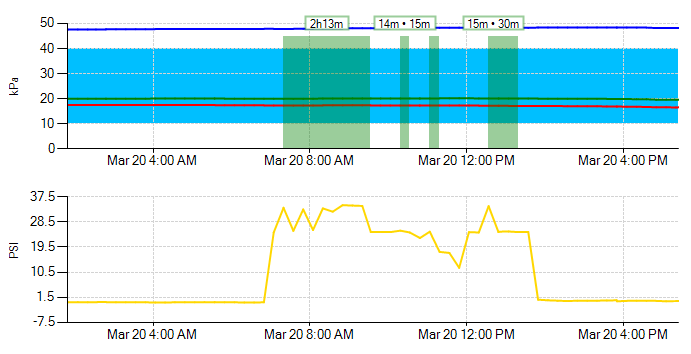

Recent applications of fertilizers have been critical for the nutritional demand of post pollinated almonds. In the below example, we can take a look at the varying pressure of a 7-hour application with fertilizer using a 25 psi trigger.

This block of almonds is using Nelson’s R5 with a purple #45 head and at 25 psi the design will apply 15.4 GPH. As we look at the pressure, we see that the system drops as low as 12 psi at the end of the fertilizer mix before picking back up above 20 psi.

At this pressure, the system is applying 13.7 to 11.7 GPH. In a 22’x18’ spacing, we vary our overall application rate from 0.07 in/hr to 0.05”/hr — a variance of 0.48” if the water was left to run for 24 hours. Drops in pressure led to an inconsistent application of fertilizer toward the end of the irrigation system.

This issue occurred because of turgid stormwater but was corrected after the filters were cleaned to restore the pump back to 700 GPM. By maintaining a constant pressure within the system, we can ensure a uniform application of materials and an even wetting pattern.

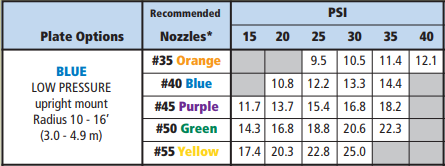

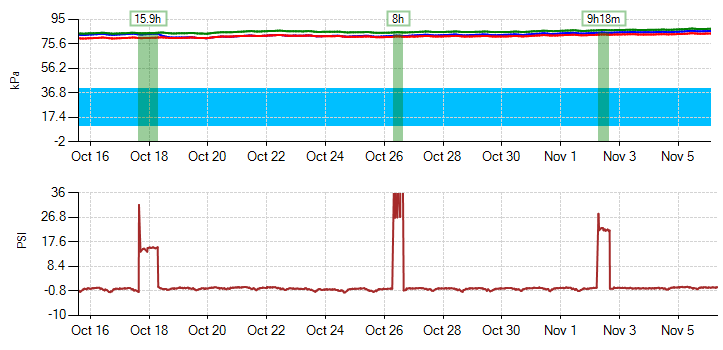

In a young walnut orchard using R10 with a #45 nozzle, it is designed to have full coverage with the required pressure. On Oct.17, the block was started, water was checked and the ranch was left overnight to finish out the 16 hours. Despite the water being on for 16 hours, only 2 hours of that irrigation met the pressure for the design. Fourteen of those hours ran without enough pressure and the wetting pattern was cut in half. Because of the clogged filter station, the block went from 35 psi down to 15 psi. In the photo below, you can see that the sprinkler is only reaching out to about 8 feet compared to its design for 17-22 feet.

Using the emitter performance pocket guide, we see that at 15 psi we are not within the designed range of the emitter and reducing our application rate by more than 20%.

The next irrigation on Oct. 26 ran during the day just to make sure the sprinklers would work properly. During this irrigation, the filter station backflushed every 1.5 to 2 hours. Further clogging issues continued until the following year where more filters were added to keep up with the pump.

Irrigation distribution uniformity plays a key role in the success of a crop stand, yield, and quality. By closely monitoring in-field pressure data we can assess the quality of our irrigations and provide our production team with the tools required to make informed decisions and optimize production.

For any questions on irrigation pressure and monitoring, please contact your local Hortau Irrigation Management Advisor.

About the Author

Irrigation Management Advisor Travis Goldman was born and raised in Watsonville and currently provides irrigation scheduling services to growers in California’s Central Valley. He graduated from UC Davis and has worked throughout California as a service technician, grower support specialist and irrigation management advisor to learn and understand every aspect of Hortau’s irrigation management platform.